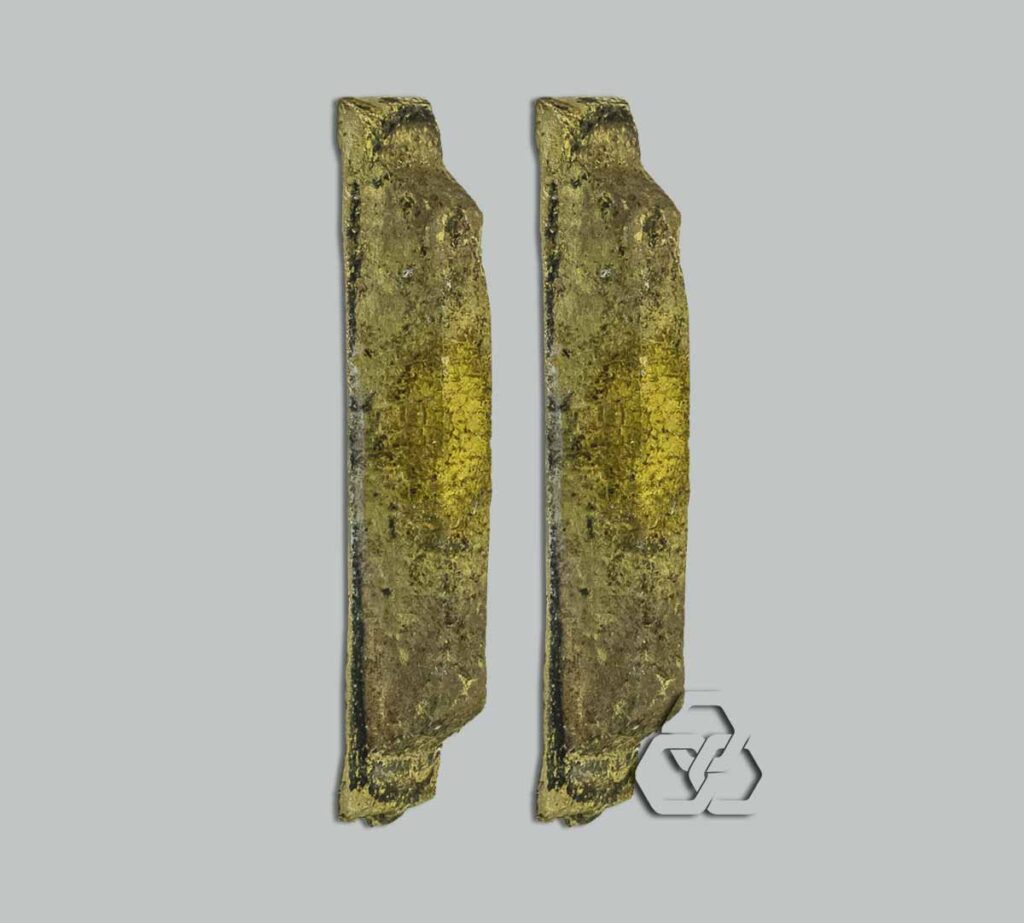

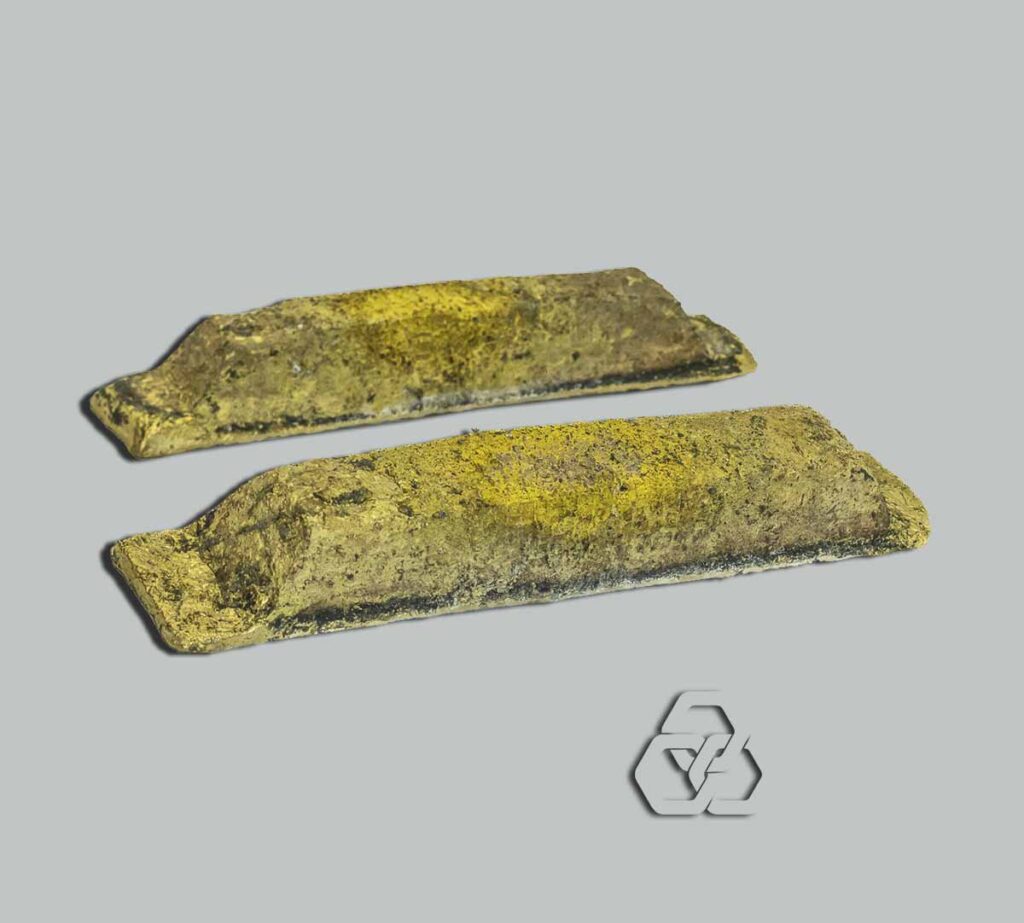

Brass Ingot for Casting

Brass ingot for casting is basically a portion of this alloy that is poured into a mold after being heated above its melting point. After cooling, the result is a brass ingot, ready for casting and subsequent manufacture of the most different kinds of parts and objects by various industrial sectors, such as: automotive, naval, aerospace, etc.

Brass ingot for casting is one of the many products that Fundição Magma manufactures and sells. We are one of the references in the national and international ingot market, produced in different kinds of metals and alloys. We achieved this position thanks to the quality of our products and as a result of our punctuality and prompt service to our customers.

Properties of Brass Ingots

There are several categories of brass alloys in use in the market. For each one, Fundação Magma produces different types of brass ingots, with different properties. The basic metals that compose and define this alloy are copper (Cu) and zinc (Zn). The two always appear in greater concentration, whatever the type of brass alloy.

To these two elements are added smaller percentages of other metals to form multiple possible alloys. Among them: tin (Es), lead (Pb), iron (Fe), nickel (Ni), manganese (Mn) and aluminum (Al). Distinct brass alloys are needed to meet industry demand for types of brass ingots with different properties.

This is how brass ingots SAE C85700 are used in the manufacture of ornamental and decorative parts in general, exploiting one of their main properties: their golden color. Brass ingots SAE 41 are used in the manufacture of parts for radiators and battery terminals, exploiting another of their properties: resistance to corrosion.

In general, brass alloys have the following general properties:

- Brass Properties

- Great ductility, which can be easily reduced to wires.

- Excellent thermal and electrical conductivity.

- High malleability, making it the suitable material for making extremely thin sheets and plates

- Good cost effectviness.

- Production versatility.

- Great resistance to corrosion.

- High mechanical strenght.

Luster (when polished, brass has an intense luster and a prominent golden color, produced by the concentration.

Brass is 100% recyclable. Its recovery consumes less water and electricity, compared to the production of brass from the corresponding primary ores. Brass recycling in Brazil recovers more than 600 thousand tons of zinc per year. Fundição Magma plays an important role in the consumption chain by recovering metals, including brass, transforming scrap into raw materials for use by large Brazilian and foreign industries.

Brass Ingot for Casting Applications

The wide diversity in the applications of brass ingots for casting has made the metal the preferred raw material by manufacturers of a large number of products with high commercial competitiveness, from commodities to items with high added value, such as:

- Applications

- Shower Heads

- Antennas

- Heaters

- Drains

- Stop valves, valves and faucets

- Washbasin mixers

- Musical instruments

- Padlocks, key chains and keys

- Weapons and ammunition cartridges

- Pots and pans

- Medical and dental instruments

- Car wheels

- Screws and nuts

- Wires

- Jewels, costume jewelry and coins

- Decorative objects

- Cores of vehicle radiators

- Nozzles and connections for compressed air

- Crane components, cams and heavy-duty supports

- Parts of hydraulic cylinders

- Naval accessories

Brass Ingots Fundição Magma

A Fundição Magma produces different types of brass ingots for casting::

- SAE STANDARD

- Brass Ingot SAE 41

- Brass Ingot SAE 43

- Brass Ingot SAE 430B

- Brass Ingot SAE 430A

- ASTM STANDARD

- (C.A. 85400)

- (C.A. 86500)

- Brass Ingot C.A. 86400

- Shell Casting Brass Ingot (C.A.85700)

- Forged Brass Ingot C.A. 37700

- Brass Ingot CLA 360

- (C.A. 86300)

- (C.A. 86200)

- Brass Ingot C.A. 46500

- Brass Ingot C.A. 67400

- Brass Ingot C.A. 35000

- Brass Ingot C.A. 21000

- Brass Ingot C.A. 22000

- Brass Ingot C.A. 23000

- Brass Ingot C.A. 86100

- Brass Ingot C.A. 24000

- Brass Ingot C.A. 26000

- Brass Ingot C.A. 27000

- Brass Ingot C.A. 85500

- Brass Ingot C.A. 46400

- Brass Ingot C.A. 85800

- POPULAR NAME

- Terra brass

- High resistance brass

- Common brass or German brass

- Forged brass

- Free cut brass

- Arsenical Naval Brass

- Silicone Brass

- Medium Lead Brass

- Tombak 95

- Tombak 90

- Red Brass

- Manganese Brass

- Brass 80%

- Cartridge brass

- Yellow Brass

- Brass 60-40

- Naval Brass

- Injection Brass

Our company has its own laboratories equipped with innovative Brunker and Spectro spectrometers, performs sample analysis of all brass ingot runs and sends a quality report to customers, along with the delivered loads.

The company offers immediate delivery for the entire line of brass ingots.