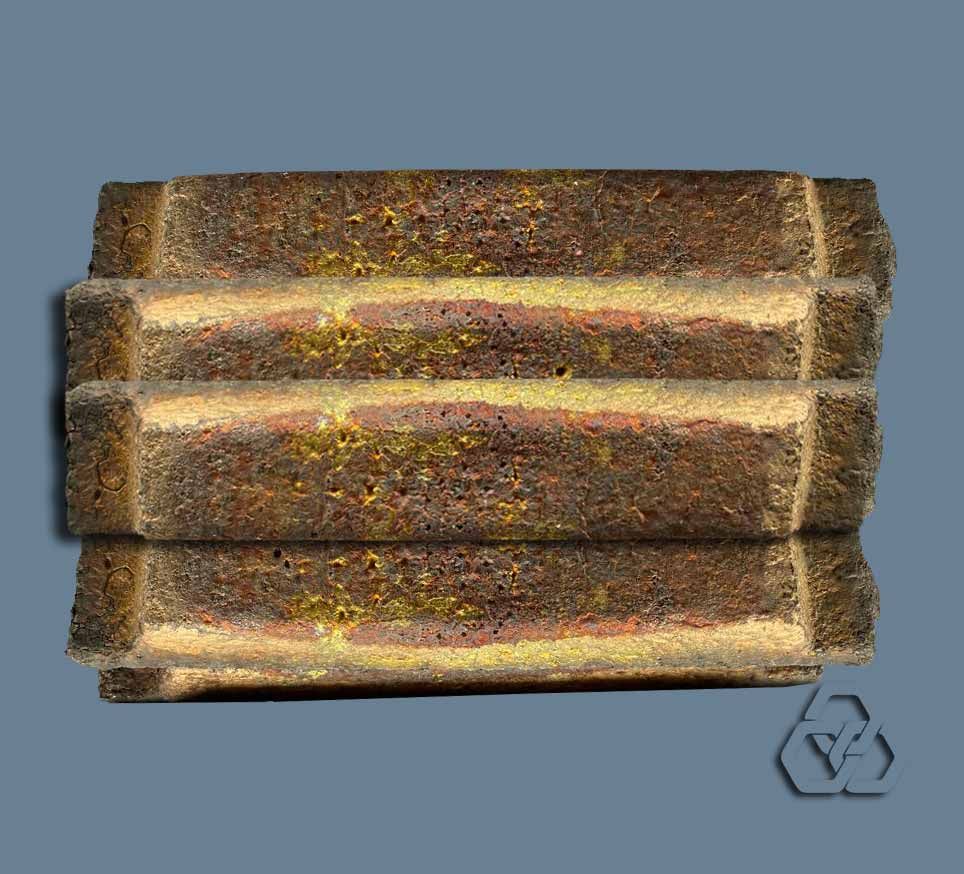

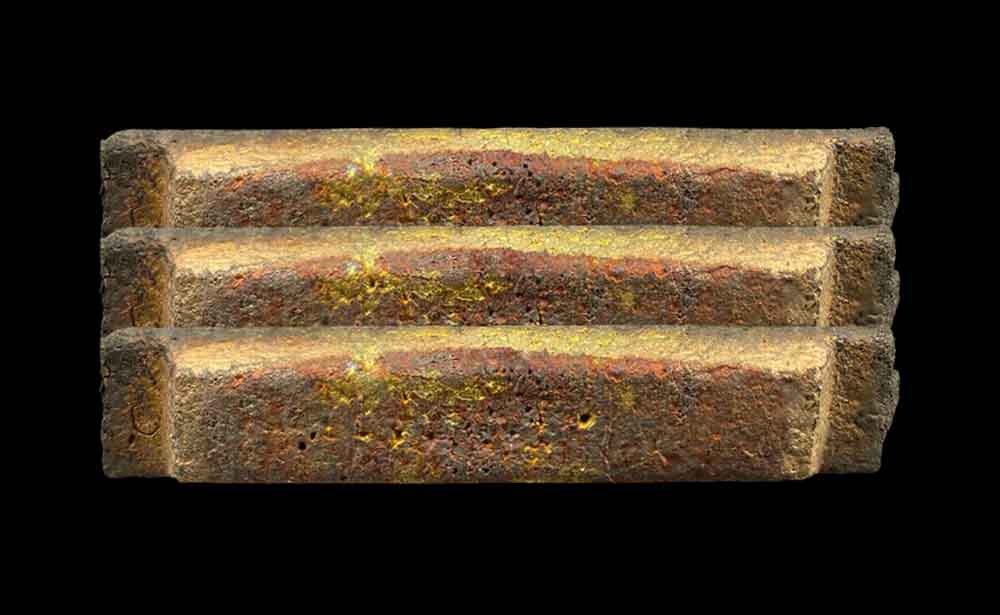

Bronze C 83.300

Bronze C 83.300 ingots produced by Fundição Magma are manufactured within the highest international quality standards. With our own sophisticated analysis laboratories, we carry out quality control of the alloy for each batch produced, to ensure that the products reach our customers with the appropriate physical and chemical characteristics.

Bronze C 83.300 is an alloy that has a high percentage of copper (up to 94%) and zinc (up to 6%), being specially formulated for casting. It has a high melting temperature and ductility.

In addition to having become a reference in the supply of bronze C83300, Fundição Magma guarantees efficiency and punctuality in delivery, in addition to excellent service and relationship with customers and partners.

Bronze C 83.300 general characteristics

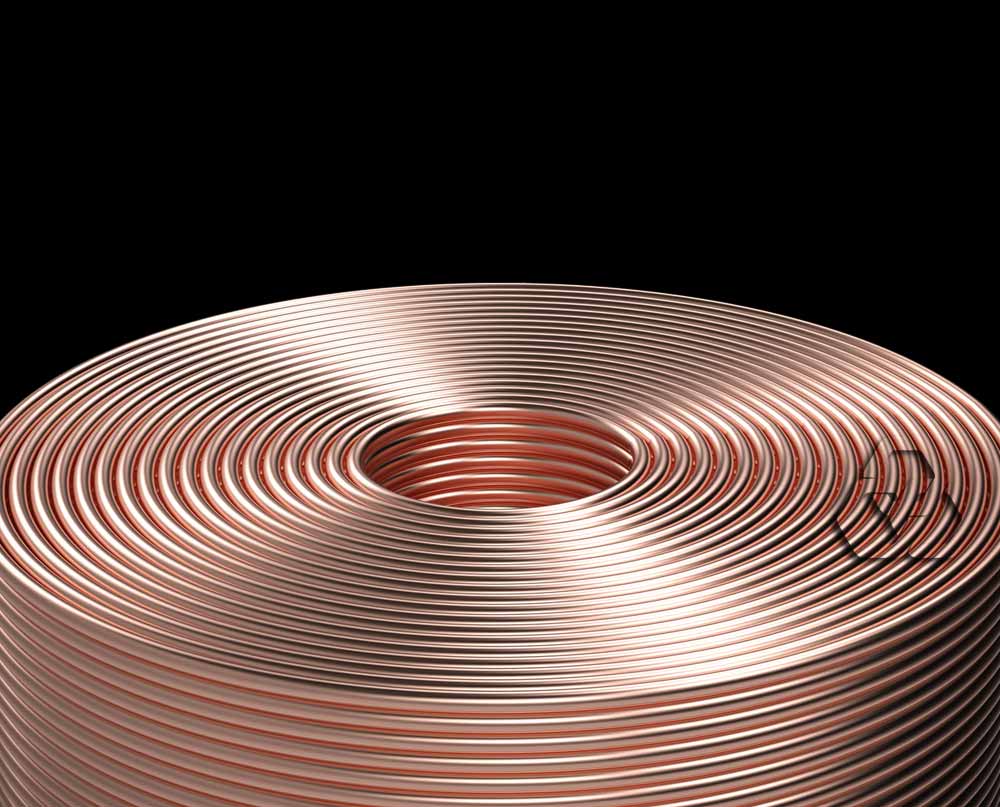

The high electrical conductivity makes this alloy the preferred one for manufacturing electrical products. Among the main characteristics and general advantages of bronze C 83.300, the most important are:

- High ductility

- High thermal and electrical conductivity

- Great cost-effectiveness

- Production versatility

- Resistance to corrosion

- Mechanical strenth

Soldering versatility completes the range of the general characteristics of bronze C 83.300. Materials in this alloy can be soldered by brazing, spot welding, and gas shielded arc welding (metal coated arc, oxyacetylene, and carbon arc welding methods are not recommended for the alloy).

Additional information: The machinability rating for cast copper UNS C83300 alloy is 35. UNS C83300 alloy has a stress relief temperature of 260 °C (500 °F). The alloy does not react to heat treatment and the temperature time for this alloy is one hour per inch of section thickness.

- Physical Characteristics

- Specific heat = 0.09 (Btu / lb / F @ 68F)

- Electrical conductivity = 32 (% IACS @ 68F)

- Density = 0.318 (lb / cu.in. @ 68F)

- Standard makers reduction = 16/3 – 1/4 (pol / ft)

- Slag = Low

- Gassing = Medium

- Fluidity = Medium

- Reduction = Medium

- Mechanical Characteristics

- Hardness (Brinell) = 35 (HB @ 500kg)

- Machinability = 35%

- Melting Range Liquidus = 1940 (F)

- Melting Range Solidus = 1886 (F)

- Modulus of elasticity (ksi) = 15.000

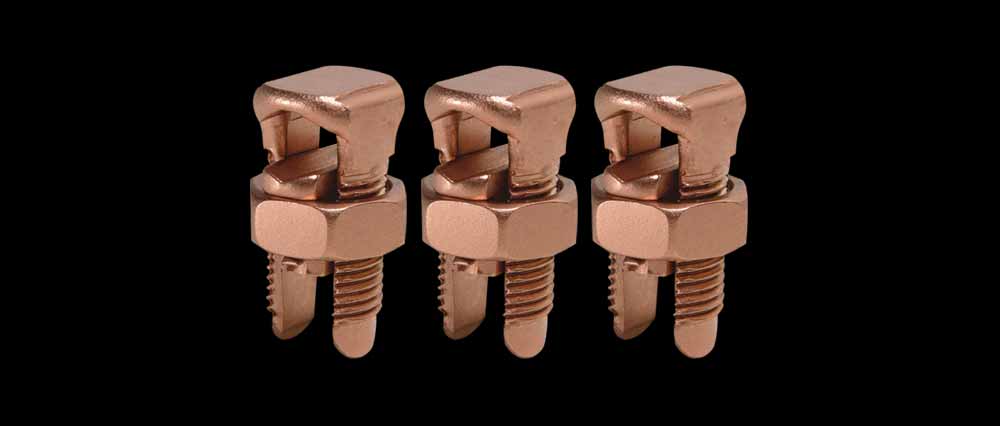

Bronze C83300 Applications

Bronze C83300 applications are multiple, but the concentration is more significant in the manufacture of products for the electrical sector:

- Applications

- Electrical cables terminal ends

- Rings manufacture

- Extension lines connectors

- Parallel clamps

- Articulated terminals

- Grounding clamps

- Chemical Composition

- CU = 92.0 – 94.0(%)

- SN = (%)1.0 – 2.0(%)

- PB = (%)1.0 – 2.0(%)

- ZN = (%)2.0 – 6.0(%)

- AL = (%)0.005(%)

Fundição Magma Bronze C83300 Ingotts

In addition to Bronze C83300 ingots, Fundição Magma produces ingots in other metals.

Learn about our complete line of metal alloy solutions!