Bronze Manufacturers

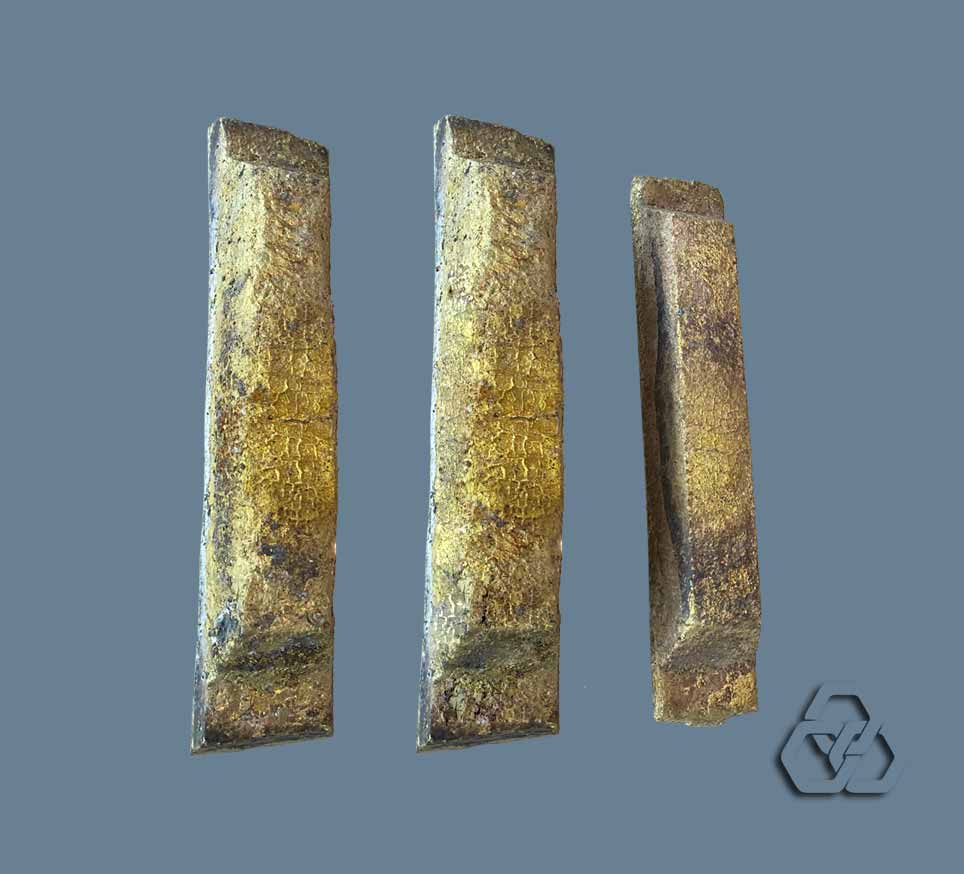

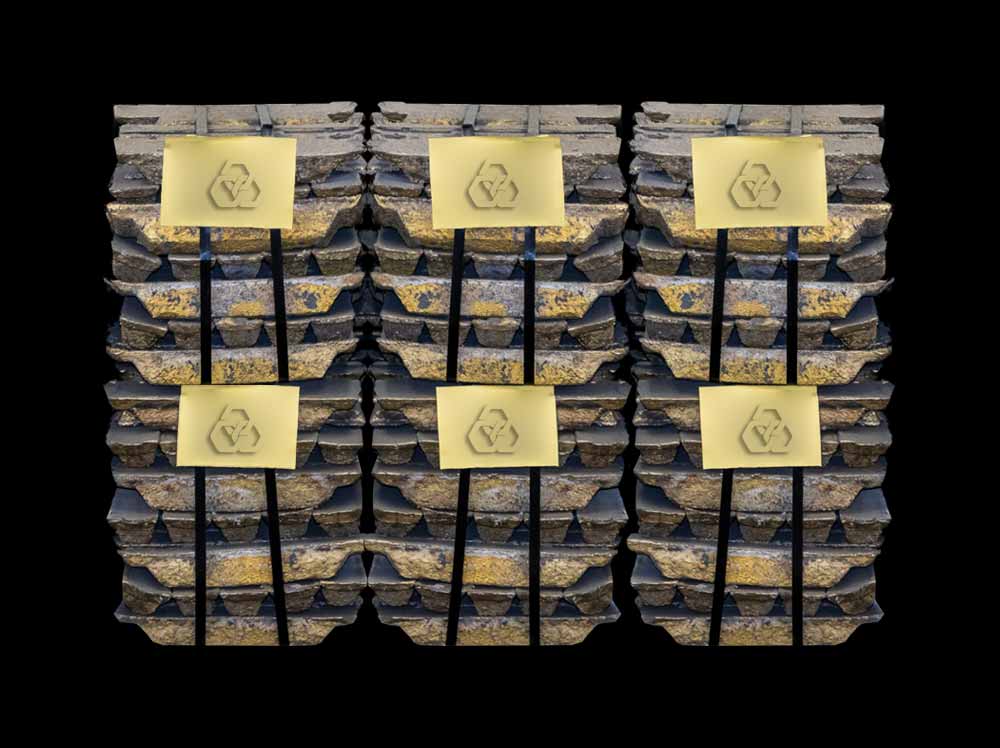

Fundição Magma is one of the most well-known bronze manufactures in Brazil, in the shape of ingots. We are recognized by the market as one of the main national references, both in product quality and in punctuality and professionalism in service.

We have an extensive experience as bronze manufactures ingots and we produce 31 different types of bronze alloys, as well as 8 different aluminum bronze alloys.

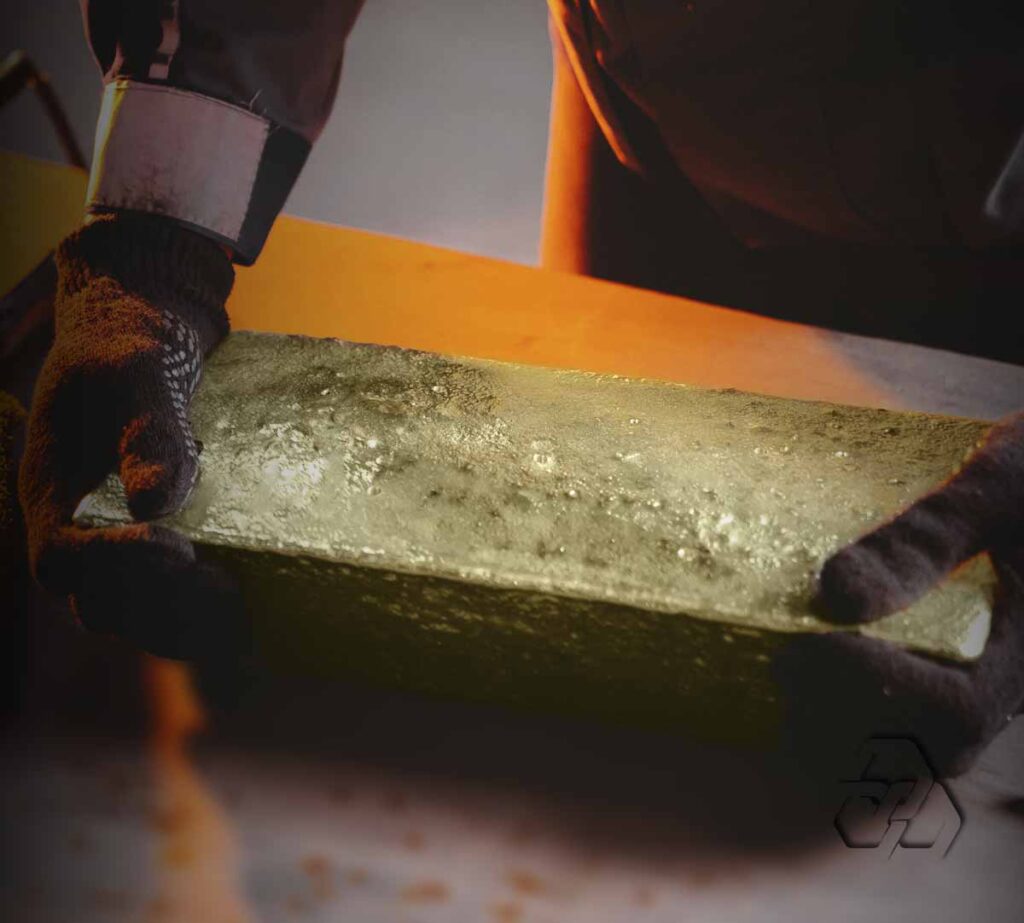

We use high technology to manufacture bronze and we carry out rigorous laboratory tests of quality control of our products, with each batch produced.

For those looking for manufacturers of bronze ingots, Fundição Magma presents itself as one of the best national options, capable of supplying bronze alloys in accordance with the specifications established in international standards, with strict observance of the reliability in the composition of the alloys.

Bronze Alloys

A metal alloy is the result of the union of two or more metals through heating and melting. The purpose of the different metal alloys is to meet certain physical and mechanical characteristics absent in pure metals. Example: bronze alloys were developed to manufacture products that were impossible to manufacture using only copper or tin separately.

In fact, bronze is now a generic name that represents a vast family of bronze alloys. All have copper and tin in common in the formulation, but they can also have added portions of zinc, aluminum, lead, nickel and manganese, to name a few. Each metal embodied into the bronze alloy gives it certain additional and different characteristics to meet the multiple needs of the industries.

While each type of copper alloy has its own particular properties, the characteristics below are very common:

- High hardness

- High melting point

- Strong streght

- Good ductility

- Great resistance to corrosion

- Excellent heat and electricity conduction

- Great finishing capacity

Bronze Purposes

Bronze purposes are countless. Industries, in general, use this family of alloys to produce, among others, items such as:

- Applications

- Jewelry and costume jewelry, such as rings, necklaces and earrings

- Medals and coins

- Statues and decorative objects on tombstones

- Screws and nuts

- Manufacturing plant tools and equipment

- Electrical appliances

- Hydraulic fittings

- Engine coating

- Gears and bearings

- Bells and musical instruments

- Tubes

- Valves

- Household utensils

Fundição Magma – Manufacturer of Bronze

Fundição Magma produces 31 types of bronze alloys, in strict compliance with the international standard SAE (Society of Automotive Engineers – USA).

As a result, our customers benefit from the faithful observance of the technical recommendations on the proper composition ingot alloys we produce.

Bronze alloys produced by Fundição Magma:

- SAE STANDARD

- Bronze SAE 40 Ingot

- Bronze SAE 622 Ingot

- Bronze SAE 660 Ingot

- Bronze SAE 620 Ingot

- Bronze SAE 63 Ingot

- Bronze SAE 64 Ingot

- Bronze SAE 62 Ingot

- Bronze SAE 65 Ingot

- Bronze SAE 640 Ingot

- Bronze SAE 66 Ingot

- Bronze SAE 67 Ingot

- Bronze SAE 88 Ingot

- Bronze SAE 621 Ingot

- Aluminum Bronze SAE 68A Ingot

- Aluminum Bronze SAE 68B Ingot

- Aluminum Bronze SAE 68C Ingot

- Aluminum Bronze SAE 68D Ingot

- ASTM STANDARD

- Bronze C.A. 83600 Ingot

- Bronze C.A. 84400 Ingot

- Bronze C.A. 92200 Ingot

- Bronze C.A. 93200 Ingot

- Bronze C.A. 90300 Ingot

- Bronze C.A. 84500 Ingot

- Bronze C.A. 52100 Ingot

- Bronze C.A. 92700 Ingot

- Bronze C.A. 93700 Ingot

- Bronze C.A. 90500 Ingot

- Bronze C.A. 90700 Ingot

- Bronze C.A. 90900 Ingot

- Bronze C.A. 92500 Ingot

- Bronze C.A. 93500 Ingot

- Bronze C.A. 93800 Ingot

- Bronze C.A. 90800 Ingot

- Bronze C.A. 92400 Ingot

- Bronze C.A. 83800 Ingot

- Bronze C.A. 92300 Ingot

- Bronze C.A. 94300 Ingot

- Bronze C.A. 94700 Ingot

- Bronze C.A. 94800 Ingot

- Bronze C.A. 52400 Ingot

- Bronze C.A. 83300 Ingot

- Bronze C.A. 87400 Ingot

- Bronze C.A. 87500 Ingot

- Bronze C.A. 87600 Ingot

- Bronze C.A. 51100 Ingot

- Bronze C.A. 89520 Ingot

- Bronze C.A. 51000 Ingot

- Bronze C.A. 87850 Ingot

- Aluminum Bronze C.A. 95200 Ingot

- Aluminum Bronze C.A. 95300 Ingot

- Aluminum Bronze C.A. 95400 Ingot

- Aluminum Bronze C.A. 95500 Ingot

- Aluminum Bronze C.A. 95600 Ingot

- Aluminum Bronze C.A. 95700 Ingot

- Aluminum Bronze C.A. 95800 Ingot

- Aluminum Bronze C.A. 64200 Ingot

- POPULAR NAME

- Terra brass

- Industrial Bronze

- Naval Bronze

- Bronze 83-7-7-3

- Tin Bronze

- Bronze 80-3-7-10

- Phosphor Bronze 8%

- Bronze 88-10-2

- Bronze Bushing

- Bronze 88-10-0-2

- Bronze 90-10

- Bronze 87-13

- Tin Bronze w/ Pb and Ni

- Bronze Sn high Pb

- Bronze Sn high Pb

- Tin Bronze 88-12

- Bronze Sn w/ Pb and Zn

- Hydraulic Bronze

- Bronze Sn w/ Zn

- Soft Bronze

- Bronze Sn, Ni

- Bronze Sn, Ni, Zn

- Phosphor Bronze 90-10

- High Conductivity Bronze

- Bronze Si, Zn

- Bronze Si, Zn

- Bronze Si, Zn

- Phosphor Bronze Sn

- Envirobrass (Se Bi loy)

- Phosphor Bronze

- Bz/Al 9A

- Bz/Al 9B

- Bz/Al 9C

- Bz/Al 9D

- Bz/Al/Si

- Bz/Al/Mn

- Bz/Al/Ni alpha

- Bz/Al/Si

Contact us and learn about our complete portfolio of metal alloy solutions!