Bronze SAE 660

Bronze SAE 660 is an alloy composed basically of copper, tin and lead, with the addition of a small percentage of zinc and nickel. The mixture gives the alloy excellent anti-friction, castability, machinability, wear and resistance corrosion properties. The presence of Zinc in the composition ensures greater ease of casting – one of the factors that make the alloy widely used in centrifugation processes.

The family to which Bronze SAE 660 belongs generates free-cutting alloys, good thermal conductivity and excellent lubricity, due to the lead content in the composition. The alloy, which is portrayed as C93200 in the ASTM standard, is also known as: C932, Bronze for bearings, SAE 660, Bronze SAE 660 and Bronze for SAE 660 bearings. Due to its strength, it is commonly used in the manufacture of bearings.

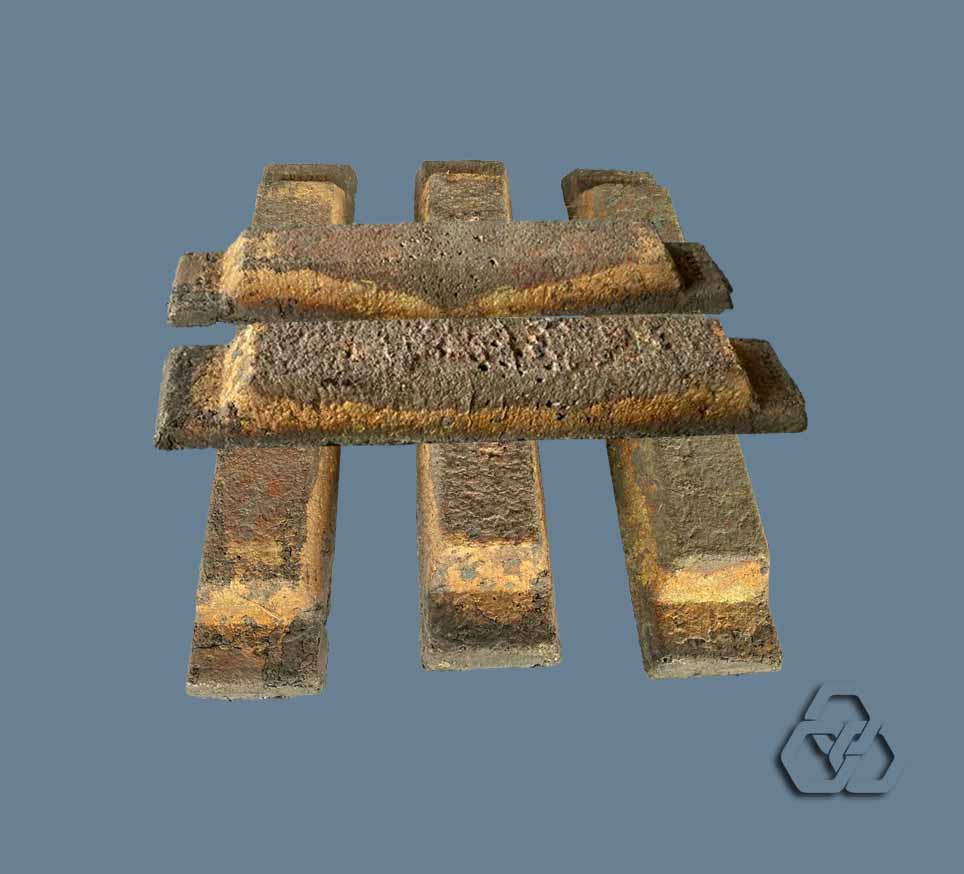

Bronze SAE 660 ingots produced by Fundição Magma comply with the highest international quality standards, with each batch being subjected to quality analysis in our own laboratories.

Bronze SAE 660 general characteristics

Although it meets numerous physical and mechanical requirements, the general characteristics of Bronze SAE 660 that stand out the most are resistance to corrosion, abrasion and wear. In order for these to be properly exploited, components manufactured in Bronze SAE 660 need to operate under ideal lubrication conditions.

Bronze SAE 660 is considered noble, due to the presence of copper and tin in the alloy composition, in higher percentages compared to other formulations.

Due to the resistance to corrosive agents and the excellent response to the most different mechanical requirements, parts and components manufactured in Bronze SAE 660 usually have a long durability, which gives the alloy an excellent cost effectiveness.

- Physical Properties

- Density: 8.85 g/cm³

- Electrical conductivity: 12.0% I.A.C.S

- Thermal conductivity: 58 w/cm.k

- Melting Point: 977ºC

- Thermal Expansion: 1,82 10-5

- Mechanical Properties

- Resistance limit: 245-294 Mpa

- Flow limit: 160 Mpa

- Elongation: 12-20%

- Hardness: 75 Brinell

- Temper: M

Bronze SAE 660 Applications

Thanks to its properties, there are multiple applications for Bronze SAE 660. Widely required by different industrial sectors, such as metallurgical, steel, chemical and naval, the alloy is one of the most known and used worldwide.

- Chemical Composition

- CU = 81.0 – 85.0(%)

- SN = 6.3 – 7.5(%)

- PB = 6.0 – 8.0(%)

- ZN = 2.0 – 4.0(%)

- NI = 1.00(%)

- FE = 0.20(%)

- AL = 0.005(%)

- Bronze SAE 660 Applications

- Rolling mills and mills bearings

- Presses bushings

- Shoes

- Backrests

- Piston pin bushings

- Sliding bushings

- Hydraulic material

- Trimmings

- Coupling elements

- Rings

- Anti-friction components

Fundição Magma Bronze SAE 660 Ingots

In addition to the Bronze SAE 660 ingots, Fundição Magma produces ingots in other metals.

Learn about our complete line of metal alloy solutions!