Bronze SAE 67

Bronze SAE 67 is an alloy of high strength, easy to cast, hydrostatic, resistant to corrosion and wear. Furthermore, it is heat treatable. It has a higher lead content, which improves machinability and friction properties. It is especially indicated for applications where lubrication can be stopped without jamming.

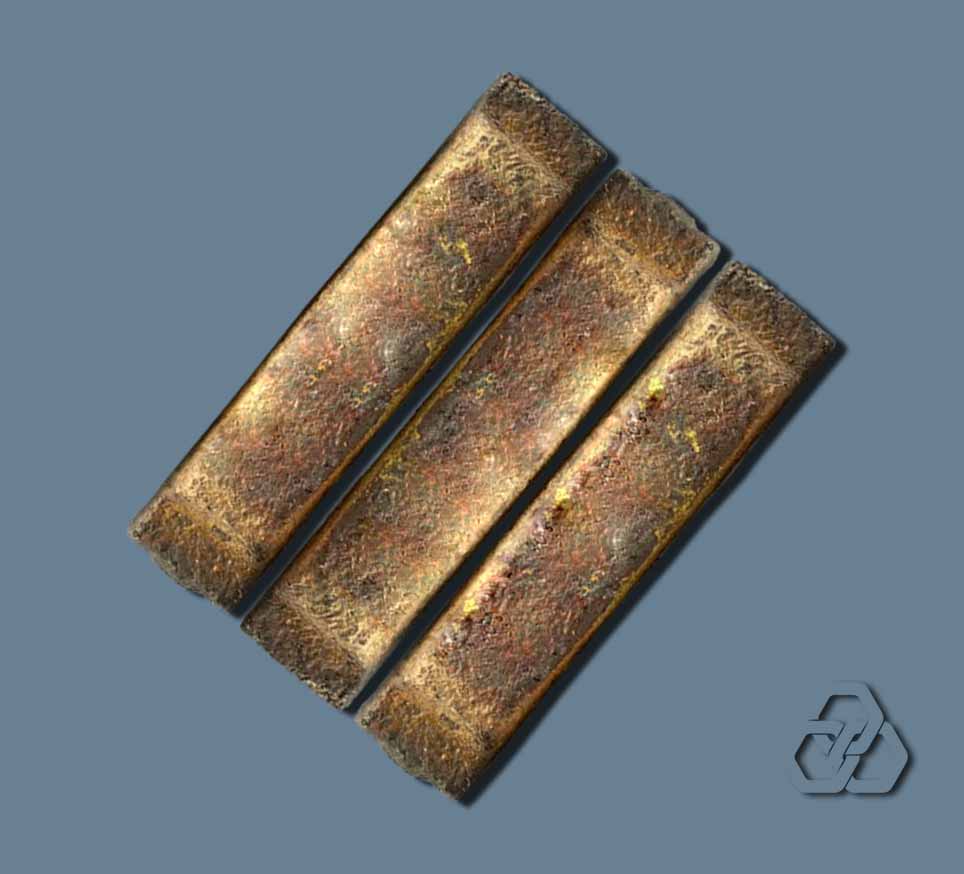

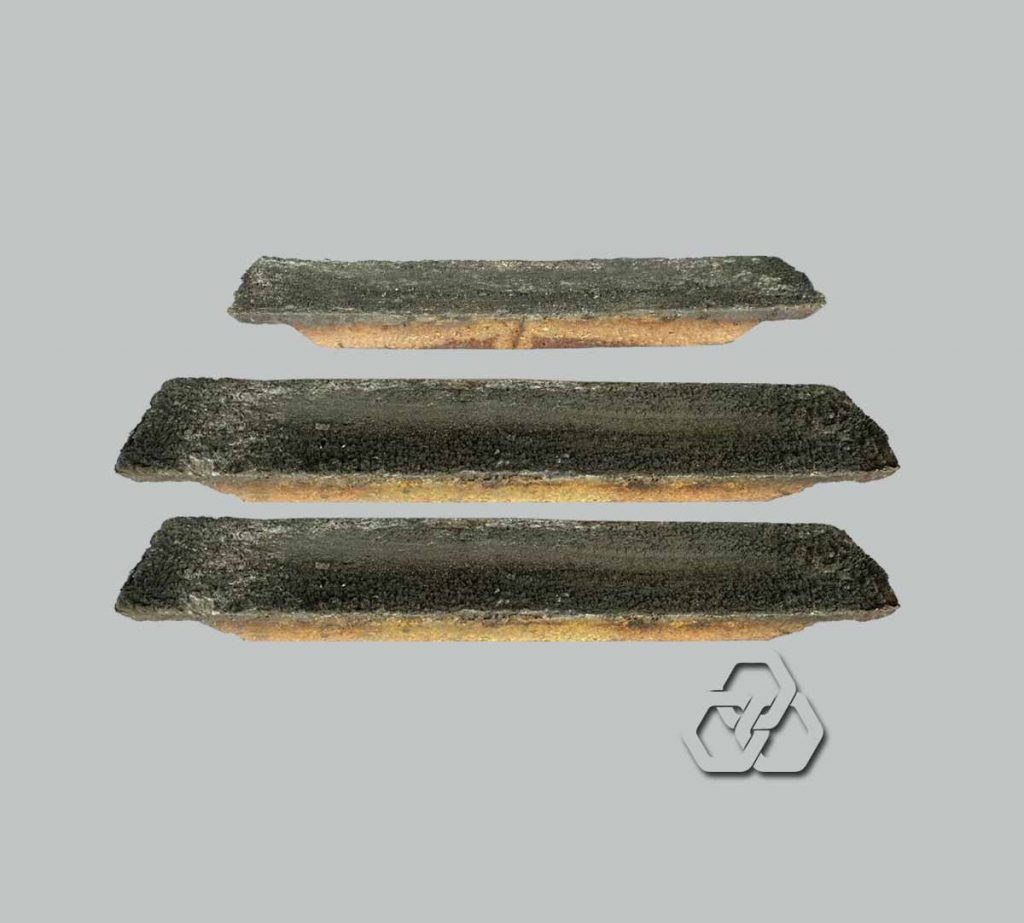

Fundição Magma produces Bronze SAE 67 ingots following the highest international standards. We have a quality control laboratory that guarantees the composition, strength and durability of the product you purchase.

Bronze SAE 67 (or ASTM/UNS C93800) has excellent machinability and friction properties due to the additional lead component. Alloy C93800 can be used in applications where lubrication can be stopped without jamming.

With excellent lubricity, high lead bronzes such as Bronze SAE 67 are ideal for bearing applications where lubrication may occasionally be interrupted during operation. These alloys perform excellently in harsh environments where foreign materials may be present. Alloys with a high lead content are capable of involving foreign bodies due to their malleable nature. And in doing it so, they protect the wear surface of main parts of an equipment or structure, like shafts, for example.

Our company is a reference in the production of ingots of Bronze SAE 67 and is characterized by quick delivery and quality service to our customers.

Bronze SAE 67 general characteristics

Bronze SAE 67 has excellent general characteristics, such as resistance to corrosion, abrasion, wear and surface fatigue. Parts manufactured in this alloy need good lubrication. It also has good thermal conductivity. The alloy has a high-density, porosity-free grain structure, resulting in reduced wear and component scrap during operation.

Bronze SAE 67 Physical Properties

- Density: 9.20 g/cm³

- Electrical Conductivity: 12.0% I.A.C.S

- Thermal conductivity: 52 w/cm.k

- Melting point: 1035-1160ºC

- Termal expansion: 1.85 10-5

Bronze SAE 67 Mechanical Properties

- Resistance limit: 260 Mpa

- Flow limit: 135 Mpa

- Enlongation: 10%

- Hardness: 65 Brinell

- Temper: D

Bronze SAE 67 Applications

Among the main applications of Bronze SAE 67 are included the manufacturing of wear parts and components for the most diverse industrial sectors:

- Medium pressure bearings

- Bushings for packing pins

- Rolling mills and mills bearings

- Presses bushings

- Shoes and backrests

- Piston pin bushings

- Sliding bushings

- Railway engine housings

- Moderate pressure bearings

- Stem bushings

- Water pump bodies

- Freight cars bearings

- Locomotive toothed bearings

- Industrial centrifuges

- Ship large bearings

Fundição Magma Bronze SAE 67 Ingots

- Bronze SAE 67 Chemical Composition

- CU = 75.0 – 79.0 (%)

- SN = 6.3 – 7.5 (%)

- PB = 13.0 – 16.0 (%)

- ZN = 0.80 (%)

- FE = 0.15 (%)

- AL = 0.005 (%)

- NI = 1.00 (%)

In addition to the bronze SAE 67 ingots, Fundição Magma produces ingots in other metals. Learn about our complete line of metal alloy solutions!