Zamak 2

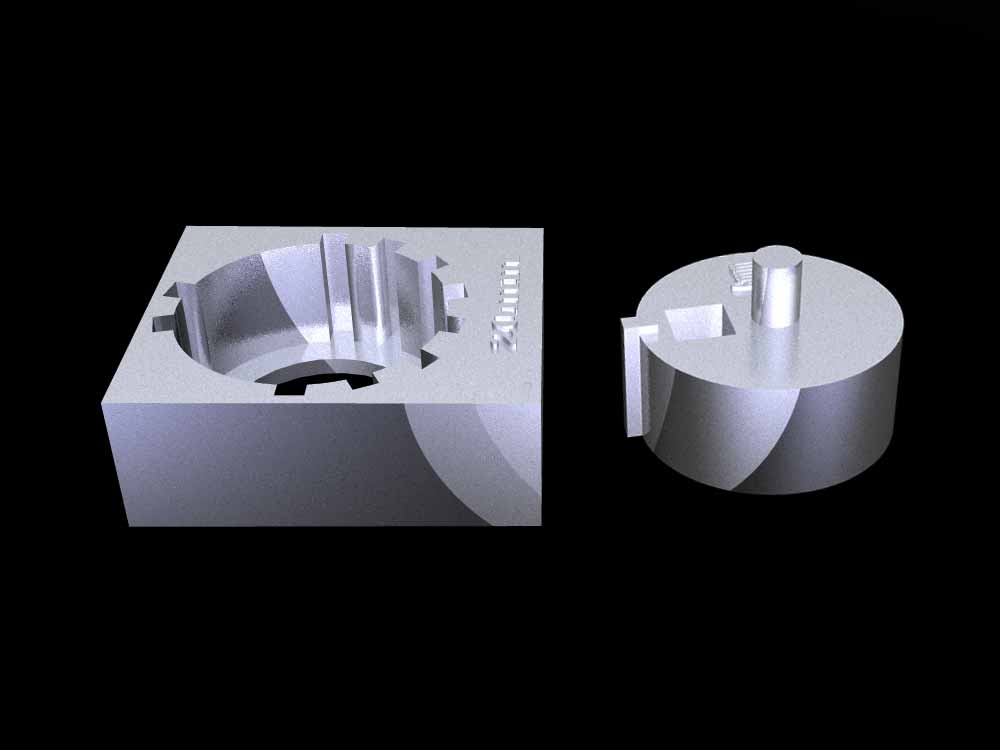

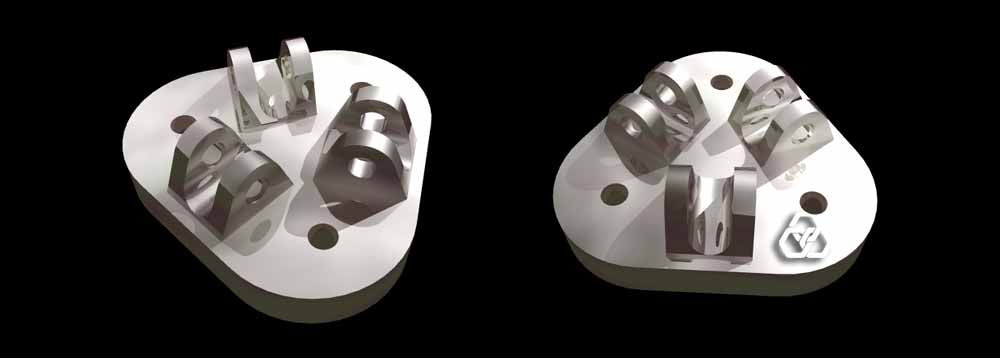

Zamac 2 (Zamak 2) is a zinc alloy that belongs to the Zamak family. In this category of alloys, it is the one with the highest degree of hardness and tensile and fatigue strength. Due to these properties, it has become the most suitable alloy for the production of tools and molds for casting and stamping.

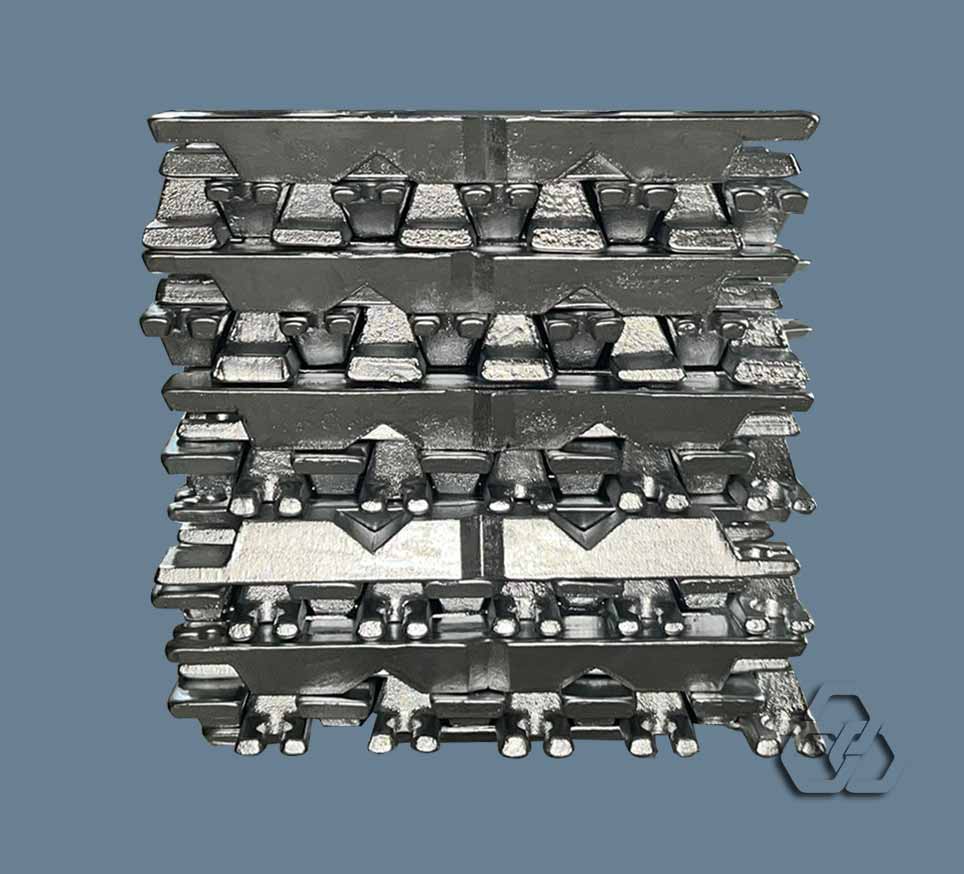

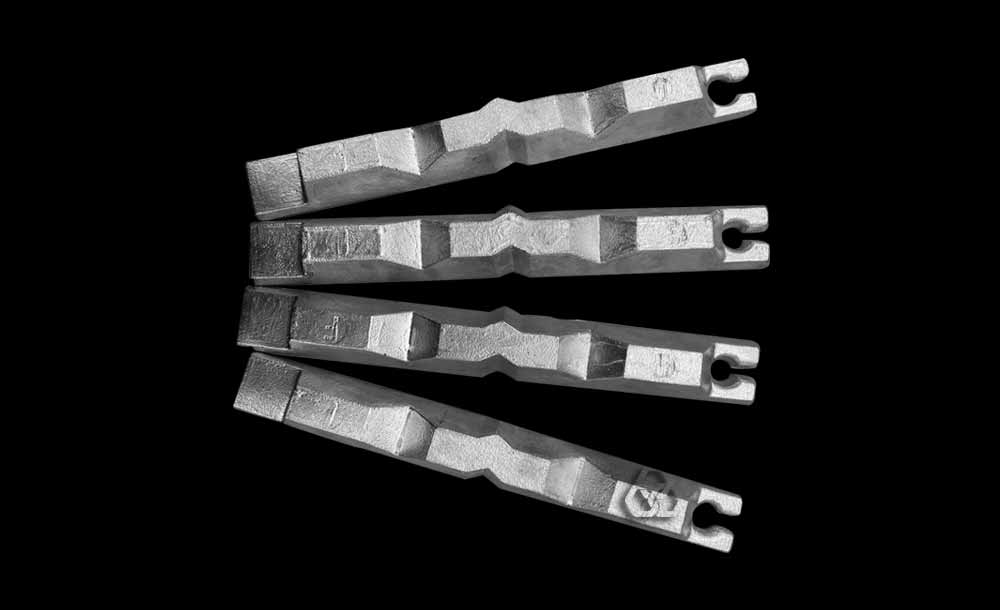

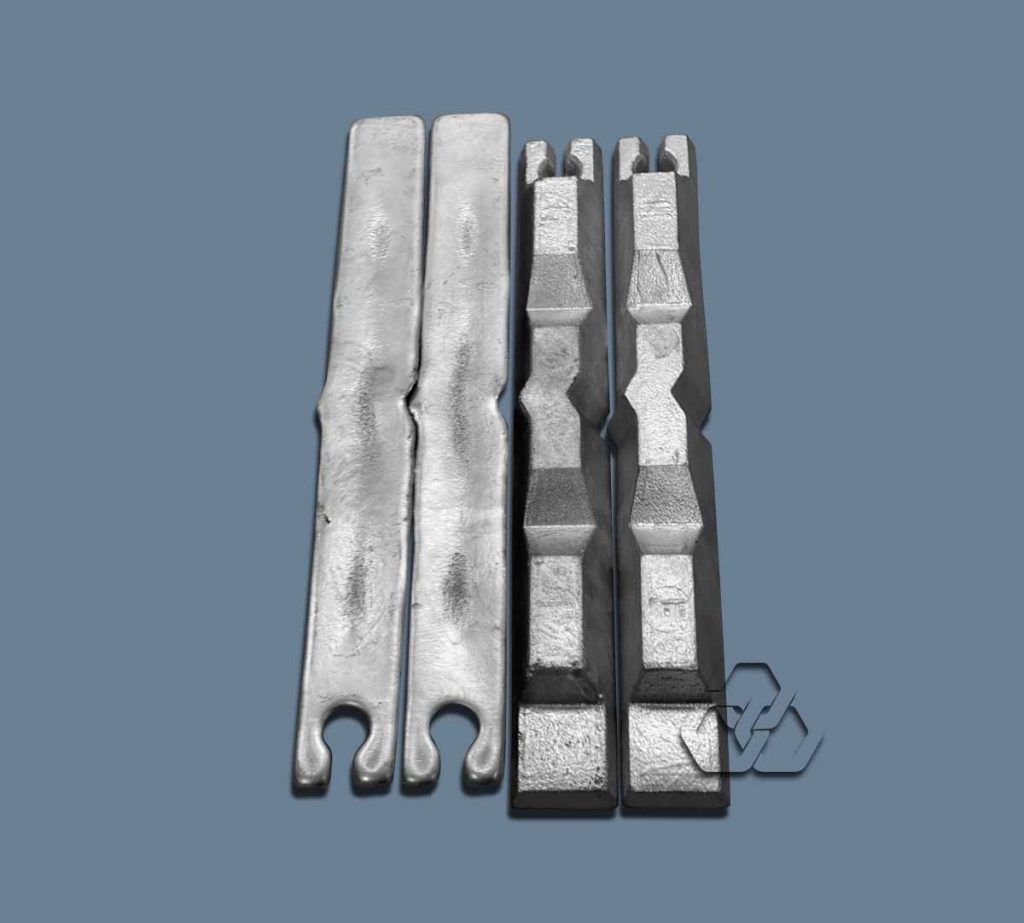

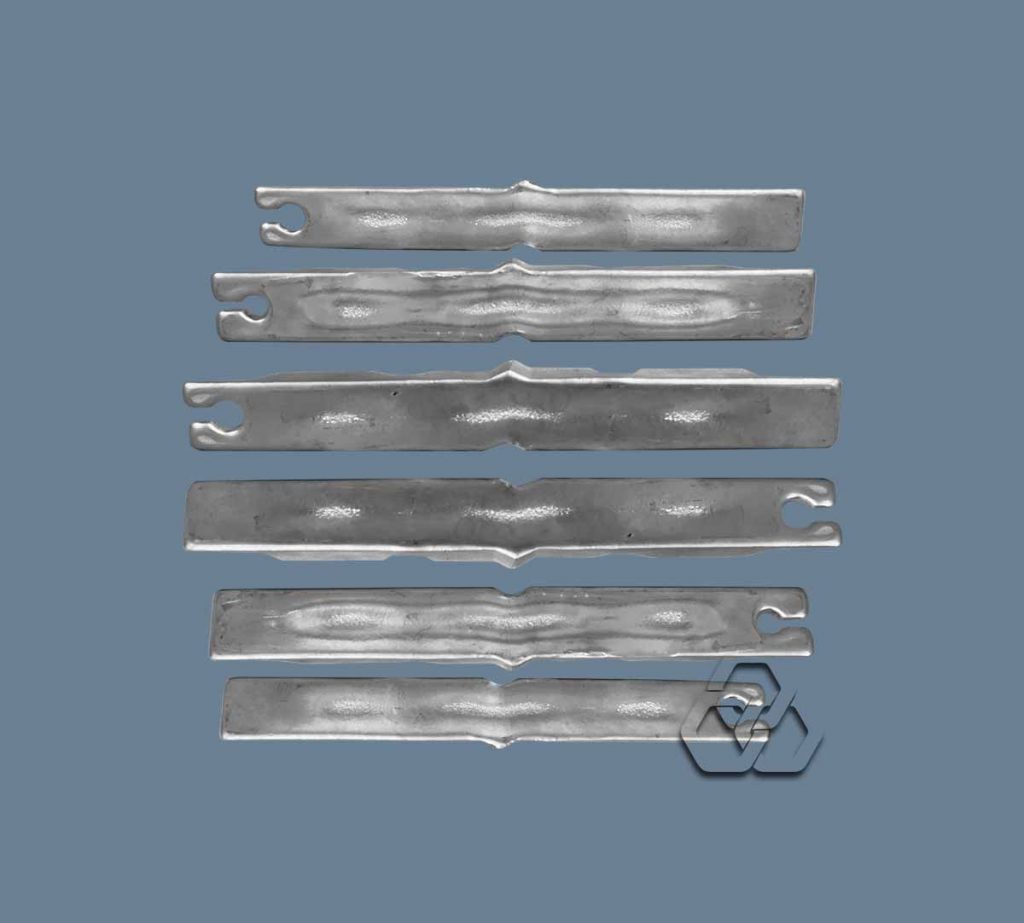

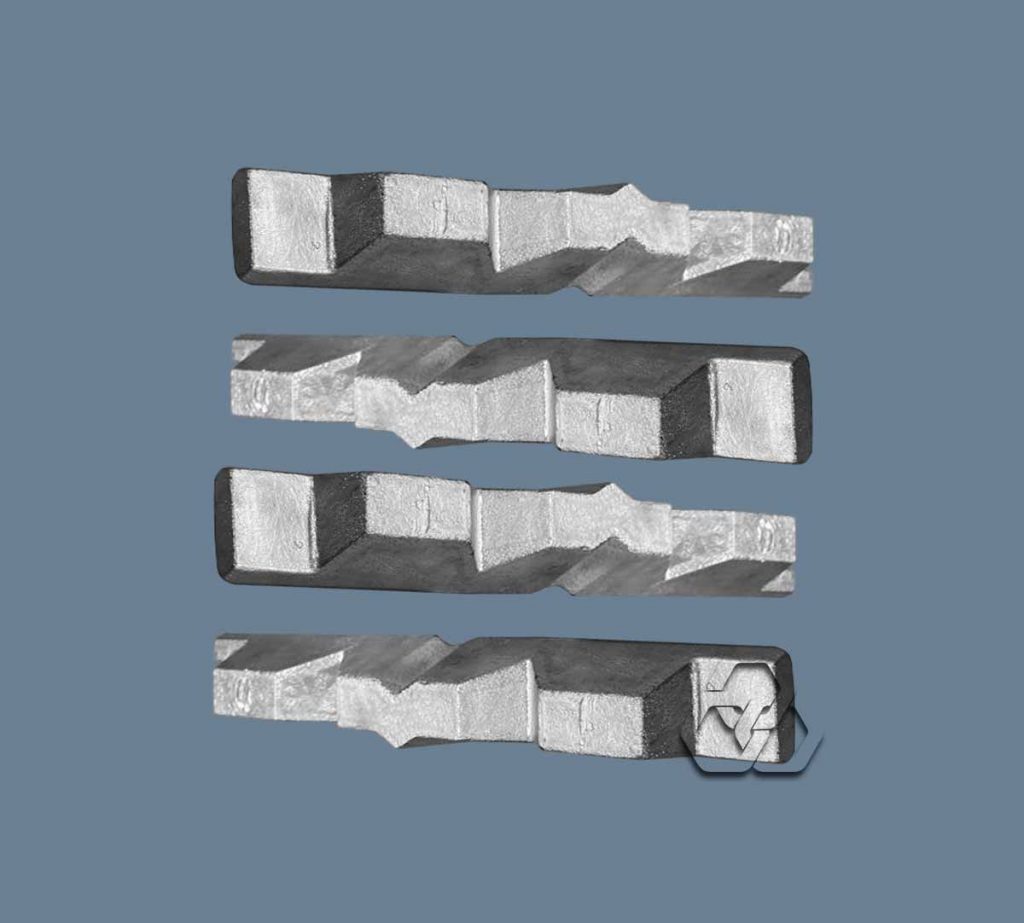

Fundição Magma produces Zamac 2 (Zamak 2) in the shape of ingots. Reference in the production and commercialization of metal alloys, our company is characterized by excellence in quality, punctuality and respect for customers and partners.

The name Zamac is actually an acronym where the letters represent the metals that form this family of alloys: Z = zinc, A = aluminum, MA = magnesium and C = copper. In the international market it is called Zamak, with K = Kupfer, which is the German word for copper.

Zamak 2 Properties

Zamak 2 stands out in the metallurgical industry due to its versatility and is often used in the manufacture of casting parts of the most varied dimensions.

Zamak alloys are a unique combination of strength, hardness, castability and excellent cost-effectiveness. As it is a versatile material, it provides high performance with the manufacture of items in series and in large volumes, without requiring the effort normally required by other types of metal from equipment and accessories.

Zamak 2 is also commercially known as Kirksite. It is the highest strength alloy of the Zamak family. This differential is due to the high level of copper concentration (3%), compared to other variations of the Zamak family (0.1% to 1.3%). As a result, Zamak 2 acquires 20% more hardness, losing, however, elasticity.

- Chemical Formula Zamac 2 (Zamak 2)

- ZnAl4Cu3

- Zamak 2 chemical composition

- • Zn = from 92.392% to 93.465%

- • Al = from 3.8% to 4.2%

- • Cu = from 2.7% to 3.3%

- • Mg = from 0.035% to 0.06%

- Zamak 2 presence of impurities

- • Pb = from 0% to 0.003%

- • Cd = from 0% to 0.003%

- • Sn = from 0% to 0.001%

- • Fe = from 0% to 0.02%

- • Ni = from 0% to 0.001%

- • Si = from 0% to 0.02%

- Zamak 2 advantages

- • Excellent casting characteristics

- • Higher creep performance

- • Excellent damping capacity and vibration attenuation

- • Durability (long-term strength and hardness)

- Zamak 2 mechanical properties

- • Elongation = 7% at 50mm

- • Tensile strength = 359Mpa

- • Yield strength (0.2%) = 283Mpa

- • Impact strenght = 47J

- • Shear strength = 317Mpa

- • Brinell Hardness (HB) = 100

- Zamak 2 physical properties

- • Density = 6.6g/cm³

- • Melting point (average ± 50) = 385°C

- • Thermal conductivity = 105W/mK

- • Coefficient of thermal expansion = 27,7µm/m°K

- • Electrical conductivity = 25% IACS

Fundição Magma Zamak 2 Ingots

Fundição Magma produces and commercializes ingots in Zamac 2 (Zamak 2), Zamak 3, Zamak 5 and Zamak 8.

Contact us and learn about our complete line of metal alloys solutions!