Zamak 8

Fundição Magma produces and supplies Zamak 8 to companies throughout Brazil and abroad and is proud to be a reference in the metal alloy market. Our company seeks excellence in quality at all stages of its production processes and is recognized for its quick delivery and polite, technical, professional and attentive service to our customers.

Zamac 8 (Zamak 8) alloy is a zinc alloy in which the aluminum concentration in the formulation is higher than in the other alloys of the ZAMAC family. It was specially developed for the use of centrifugal casting in the manufacture of small pieces, such as costume jewelry, which require a delicate finish and a high level of detail.

Zamak 8 is widely used in the centrifugal casting process. It has excellent finishing and plating characteristics, making it ideal for both functional and decorative applications. It offers greater strength, hardness and creep properties than any other zinc alloy. It is the only alloy that can be cast in a hot chamber.

Zamak 8 properties

Zinc alloys are known as Zamac (or Zamak). The acronym is formed by the initial letters of the elements of its formulation:

- Z – Zinc

- A – Aluminum

- MA – Magnesium

- C – Copper (or K for Kupfer, “copper” in German)

Each of these components present in zinc alloys gives Zamak distinct characteristics:

Aluminum: Increases fluidity and refines the grain. Increases the mechanical strength and hardness of zinc.

Copper: Increases resistance to corrosion and creep. On the other hand, it decreases ductility.

Magnesium: Decreases susceptibility to intergranular corrosion caused by impurities.

In general, the zinc alloys of the Zamac family have good resistance to corrosion, tensile strength, impact strength and wear. And they are easy to machine, mechanically mold and, mainly, cast. The ease of casting is due to its low melting point (an average of 420° C).

- Zamac 8 (Zamak 8) chemical composition

- Al = 8.2% – 8.8%

- Cu = 0.9% – 1.3%

- Mg = 0.02% – 0.03%

- Fe = 0.035%

- Pb = 0.005%

- Cd = 0.003%

- Sn = 0.002%

- Zn = Difference

- Zamac 8 (Zamak 8) mechanical properties

- Tensile strenght = 374 Mpa

- Yield strenght (0,2%) = 290 MPa

- Impact stenght = 42 J

- Shear strenght = 275 MPa

- Brinell hardness (HB) = 103

- Zamac 8 (Zamak 8) physical properties

- Density = 6.3g/cm3

- Melting point (average +/- 50) = 390 °C

- Thermal conductivity = 115W/m°K

- Coefficient of thermal expansion = 23.3 µm/m°K

- Electrical conductivity = 27.7% IACS

Zamac 8 applications

Among the different kinds of applications of the alloy, its use in the manufacture of the following items stands out:

- Faucets and locks

- Buckles for belts and shoes

- Rivets and embellishments for bags

- Jewelry

- Gas valves

- Blenders, mixers and fans housings

- Refrigerator hinges

- Watch components

- Radio and television grids

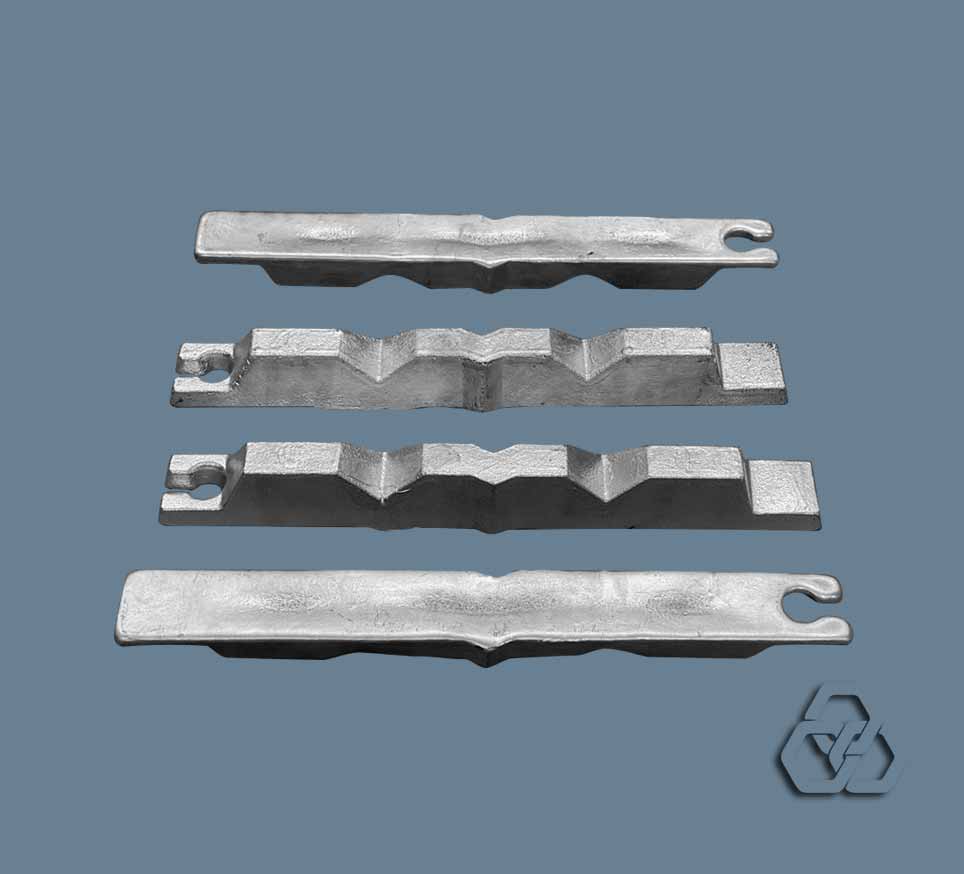

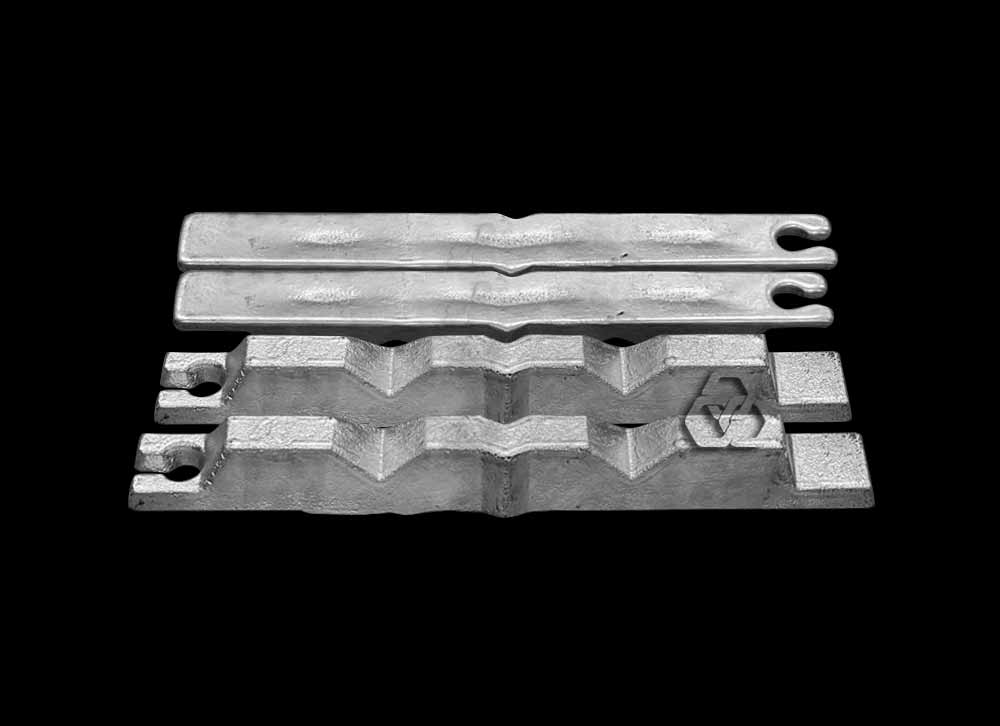

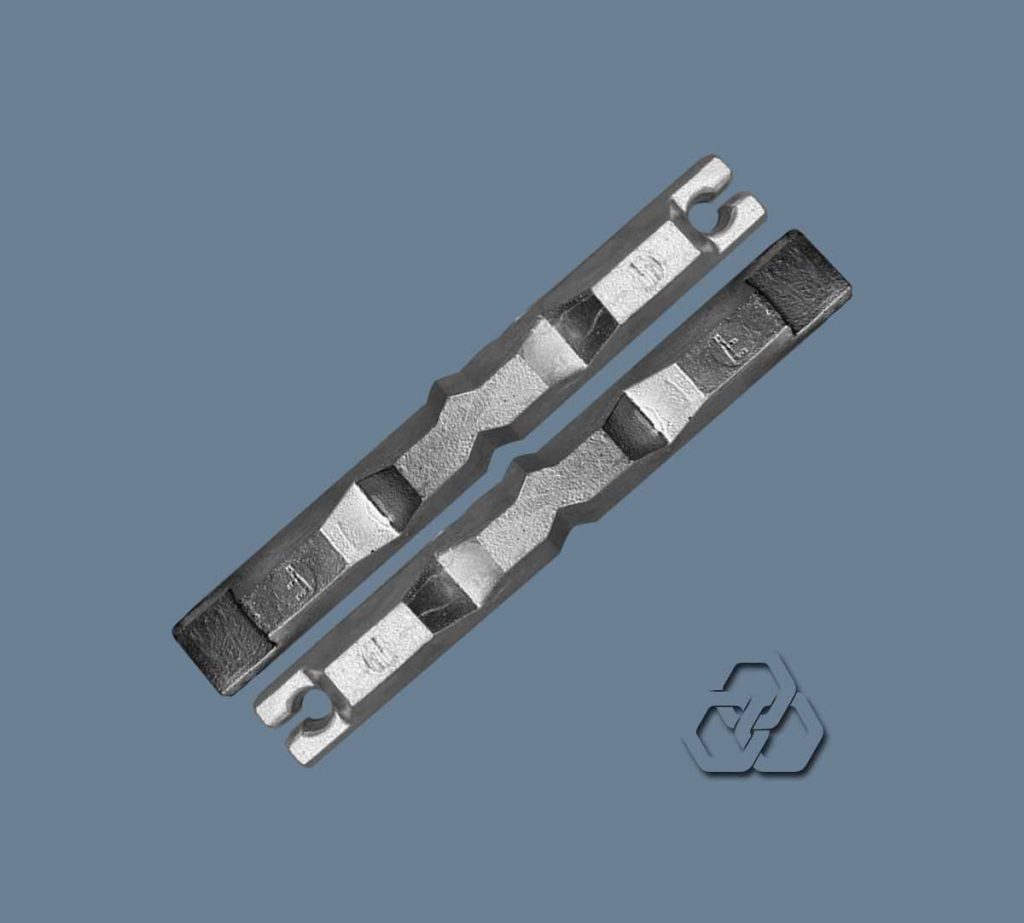

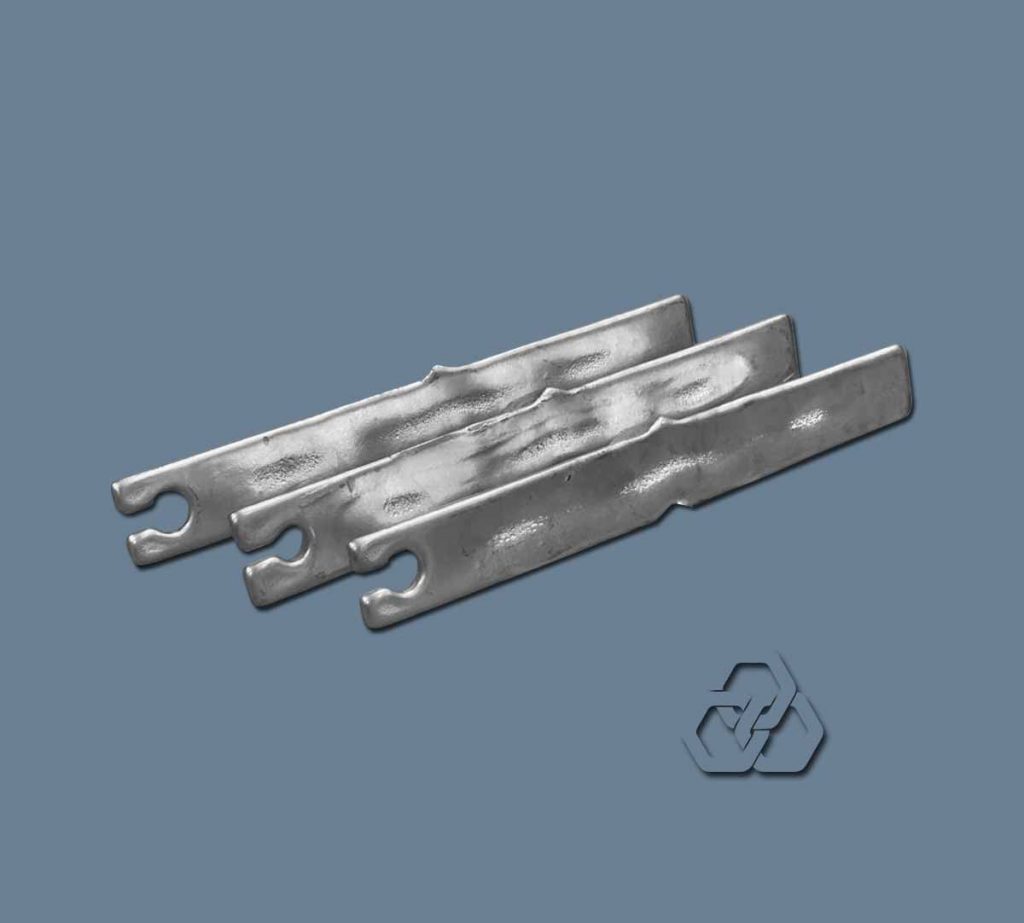

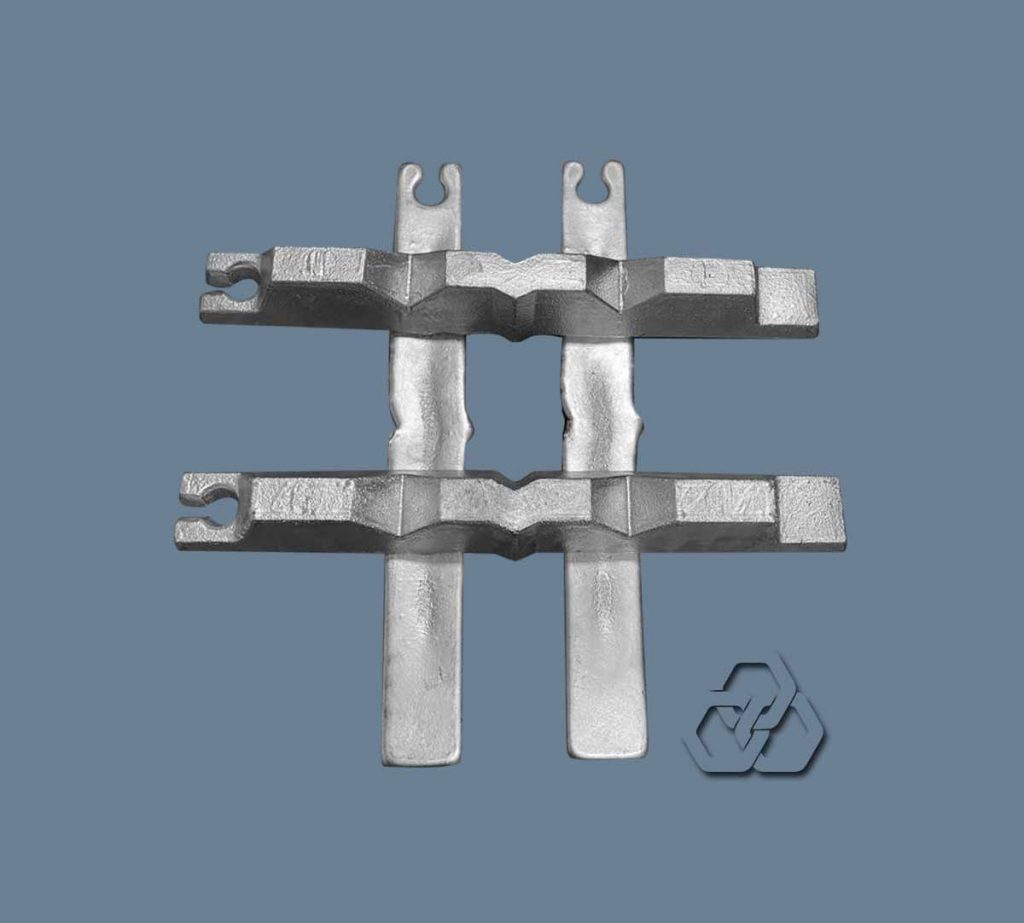

Fundição Magma Zamak 8 Ingots

Zamac (or Zamak) zinc alloys prominently present in our portfolio of metal alloy solutions. In addition to it, we also produce other alloys from the ZAMAK family: ZAMAK 2, ZAMAK 3 and ZAMAK 5.

Contact us and learn about our complete line of products!